Environment

We strive to preserve natural resources and adopt sustainable practices across our operations to contribute towards a greener future. Along with the use of innovative technology, we foster environmental consciousness to adopt a holistic approach to environmental stewardship.

19,220MT

Total Waste Recycled

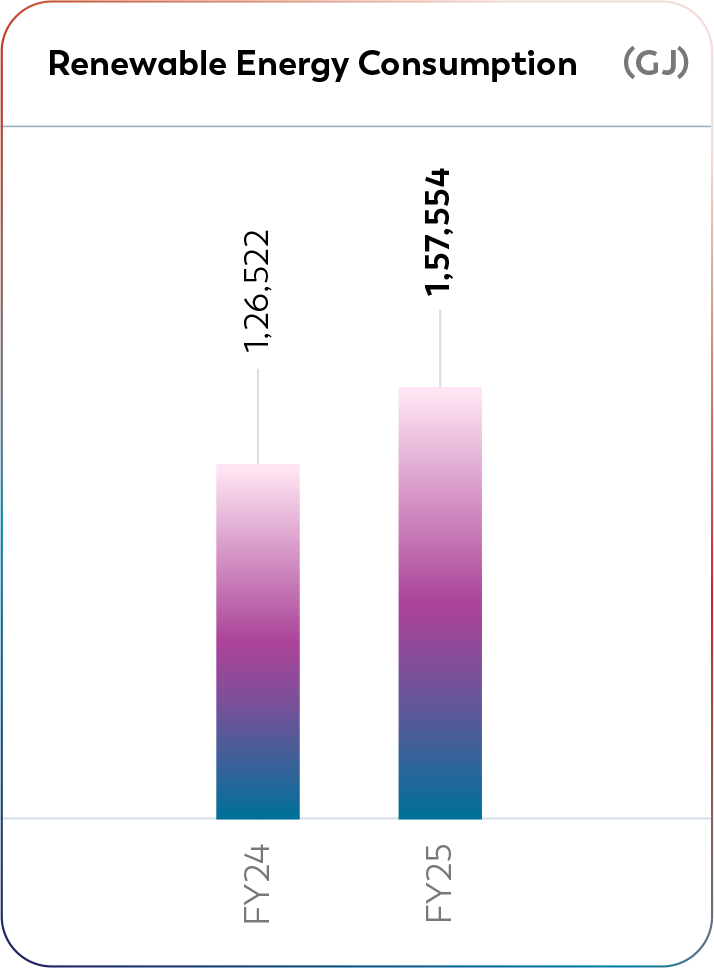

1,57,554GJ

Total Energy Consumed from Renewable Sources

SDGs Impacted

Linkage of Capitals

FFinancial Capital

Allocated funds towards key areas including energy efficiency, waste management and water conservation, among others

MManufacturing Capital

Enhancing efficiency to achieve greater outcomes with fewer resources

IIntellectual Capital

Transforming into a digital-first organisation

HHuman Capital

Collaborating with employees to ensure alignment with our sustainability agenda

SSocial and Relationship Capital

Directing CSR initiatives to support the preservation and enhancement of natural capital

NNatural Capital

Allocated funds to support environmental initiatives

Material Topics

1Biodiversity & Nature Protection

2Circular Economy & Waste Management

3Climate Change & Energy Strategy

4 R&D, Innovation & Product Stewardship

5Water Stewardship

15Responsible Sourcing

Our Goals and Targets for Environment

50%

Renewable electricity consumption

At least 1

Net zero product

Zero

Waste to landfill

30%

Recycled water usage

Our Approach to Environment

At Polycab, we harness innovative technologies and sustainable practices to minimise our environmental footprint, lower emissions and conserve natural resources. Our strategy encompasses continuous environmental monitoring and a strong emphasis on integrating renewable energy sources. We actively engage our workforce and stakeholders, fostering awareness and participation in our environmental objectives, thereby reinforcing our collective responsibility towards a greener, more sustainable future.

Key Topics Discussed

- Energy management

- GHG emissions reduction

- Water management

- Waste management

Energy Management

We implemented targeted strategies to improve energy efficiency and increased the integration of renewable energy into our operations. It empowers us to address concerns related to climate change, reduce operational costs and ensure long-term business sustainability.

Driving Energy Efficiency

- Energy-efficient Manufacturing Practices: Energy efficiency has been embedded in operations through lean manufacturing, TPM (Total Productive Maintenance) and routine energy audits, optimising power consumption and reducing losses

- ISO 50001 Certification: Major manufacturing sites are certified under ISO 50001:2018 Energy Management Systems, reinforcing a structured approach to continuous energy performance improvement

- Smart Monitoring and Automation: Energy-intensive processes are increasingly equipped with real-time monitoring and control systems to track consumption patterns and flag inefficiencies.

- Advanced Power Management: Installation of 2,650 KVAR and 1,150A Active Harmonic Filter (AHF) Hybrid Power Factor Control Panels has enhanced energy quality and reduced harmonic distortion across operations.

Towards a Sustainable Future

Our rural development programmes align with:

National Missions

- Swachh Bharat Abhiyan

- National Afforestation Programme

- Mission LiFE

- Aspirational Blocks Programme

- Natural Farming Mission

SDGs Impacted

GHG Emissions Reduction

We are proactively aiming to reduce GHG emissions. Through the adoption of strategic initiatives, we strive to contribute towards a better future.

GHG Emission Reduction Actions

- Expanded Renewable Energy Use: We raised our renewable energy consumption to 43.76 million kilowatt-hours, now covering 17% of our total electricity use.

- Lowered Carbon Emissions: We reduced 31,336 tonnes of CO2 — 14,285 tonnes from captive solar and wind and 17,051 tonnes through bilateral renewable sources.

- Installed Rooftop Solar Systems: New solar capacity of 1.972 MW and 1.273 MW were added at our Daman and Halol units respectively.

- Secured Renewable Energy Agreements: We entered bilateral deals for 1.6 MW of wind energy and a 3.71 MW wind-solar hybrid setup.

- Commissioned Wind and Solar Projects: We set up an 8.1 MW windmill and a 9.535 MW solar plant, expanding our clean energy infrastructure.

- Built Total Capacity to 32.755 MW: Our combined renewable energy capacity now totals 32.755 MW, reinforcing our shift towards low-carbon operations.

GHG Emissions

29,061 MTCO2 e

Scope 1 emissions

1,55,118 MTCO2 e

Scope 2 emissions

8.40 MTCO2/ `crore

Total Scope 1 and Scope 2 emission intensity per crore rupee of turnover

Air Emissions

23.4 ug/m3

NOx

27 ug/m3

SOx

68.4 ug/m3

Particulate Matter (PM)

Water Management

We have adopted innovative methods to significantly minimise water consumption.

Water Management Actions

- Adoption of Water-saving Technologies: We’ve introduced efficient watersaving systems into our manufacturing processes to lower our overall water use.

- Upgrades in Water Treatment: We improved our effluent and sewage treatment plants with advanced filtration and purification to increase water recycling and meet high reuse standards

- Smart Irrigation Systems: Our landscaped areas now use smart irrigation that adjusts water use based on weather forecasts and soil moisture, helping us conserve water more effectively.

- Strict Regulatory Compliance: We follow all CPCB and SPCB guidelines closely to ensure our water practices meet required standards.

- Commitment to Zero Liquid Discharge: We operate under a Zero Liquid Discharge system, recycling all water used and avoiding any discharge, aligning with our goal of responsible and sustainable water use.

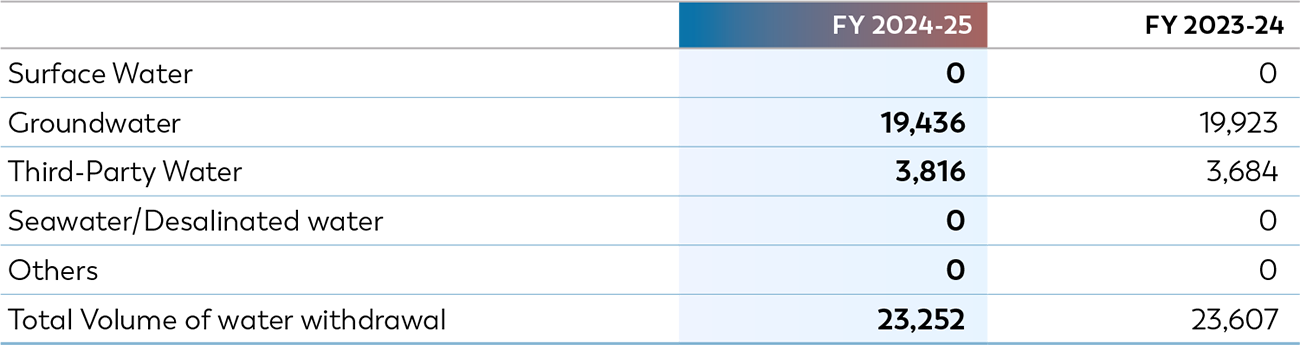

23,252 KL

Total Water Consumption

1.06 KL/` crore

Water intensity per crore rupee of turnover

Water Withdrawal (KL)

Waste Management

Waste reduction remains a key focus area. We have incorporated recycling and waste disposal methods to minimise our ecological footprint. Further, to enhance resource efficiency and strengthen the foundation of a sustainable future, we continue to adopt the principles of a circular economy.

Waste Management and Circularity

Minimising Waste at Source

We have reduced waste generation through better processes and lean manufacturing. This has helped cut excess across every stage of the product lifecycle.

Improving Recycling Efforts

We now recover around 70% of industrial wastewater and have reduced the amount of waste sent to landfills through structured recycling programmes.

Responsible Disposal of Non Recyclables

For waste that cannot be reused, we have adopted advanced thermal treatment and are exploring bioconversion methods to lower environmental impact.

Applying Circular Principles

We are working with suppliers to use more recyclable and reusable materials in our products and packaging, keeping more materials in use for longer.

Using Safer Materials

Our green wires portfolio continues to grow using non-hazardous materials that meet RoHS and REACH standards. This supports waste reduction and ensures our products are safer for people and the environment.

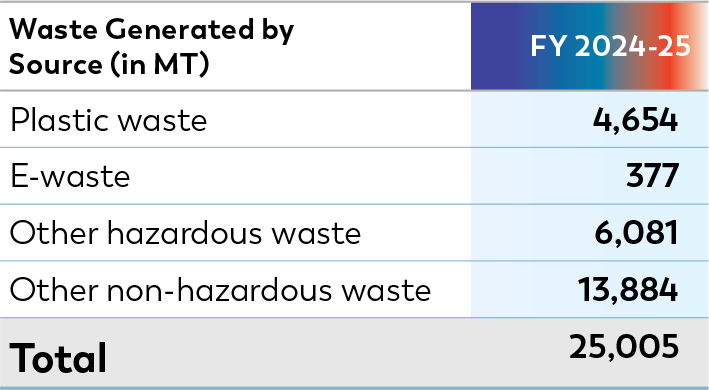

25,005 MT

Waste Generated

19,220 MT

Waste Recovered (recycling and reuse)

5,785 MT

Waste Disposed