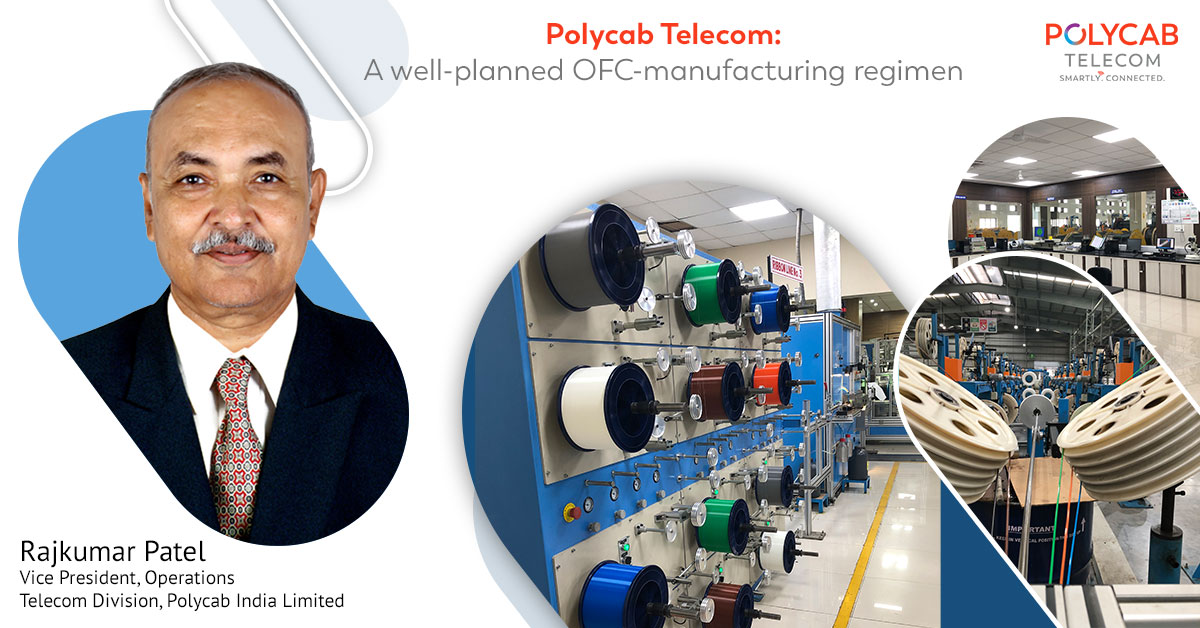

Polycab Telecom, a division of Polycab India Ltd., is engaged in manufacturing and distribution of Optical Fibre Cables (OFCs). With a high degree of in-house Backward Integration and Automation capabilities, we offer global, innovative and scalable fibre-optic cabling solutions to support the deployment of high-speed broadband-networks for across all segments. We’ve a state-of-the-art manufacturing facility, spread over 40000+ sq ms and a build-up area of 20000+ sq ms, where we innovate and integrate technologies to create world-class OFCs, from 6 cores to 576 cores.

We execute an uninterrupted sequence of processes in OFC-manufacturing, which starts with colouring of fibres. High-grade fibres are coloured to facilitate their simple identification. UV Curable inks are applied on the transparent fibres with the help of our high-tech colouring machines. The fibres are then treated with UV-radiation and get winded in the spool. Specially-designed high-speed Dual Take-ups and Dual Pay-offs in these machines increase the productivity and reduce the manufacturing cost appreciably. Through Ribbon Technology, fibre-cores of maximum density get packed into the most achievable compact bunch of fibres. We’ve a highly purposive machine, only-of-its-kind in Asia and second in the world, which helps us perform an efficient process to manage larger number of fibres in the installations. These tailor-made Ribbon Machines are powered with Dual Take-ups that enable production of 2 ribbons of 6 fibres each at a time. We have a well-equipped facility, where the Buffering or secondary coating process is done. Coming from fibre pay off or ribbon pay off, as per the cable-manufacturing specifications, the coloured fibres or the ribbons then pass through the Extruder Unit to get loose tubes around them. Working as a cushioning element, the jelly inside gives them protection against water-ingress. All the Buffering Lines are equipped with dual take-offs, gel-filled tubes set-ups, dry tubes set-ups and rotating ribbon pay-offs. Next in the Stranding Process, the loose tubes are stranded around a Central Strength Element. Numerous loose tubes from payoffs are stranded around the FRP Rods. A special unit, called SZ Oscillator, creates SZ-pattern in stranding. There are 2 types of SZ Core, Dry Core and Wet Core. In case of Dry Core, Water Blocking Tape is applied longitudinally over the Core with Water Swellable Yarns. In the case of Wet Core, it is flooded with Thixotropic Jelly and gets bound with the Polyester Tape. The SZ Core passes through various stages of Sheathing, where different metallic and non-metallic armouring and strengthening members are applied to it as per the cable-specifications. Most common elements are Glass or Aramid Yarn and ECCS or SS Tapes. The cables go through the extrusion, that provides them high-quality outer jackets. The premium standard compounds like high-density Polyethylene, low-smoke zero Halogen and Nylon PA-12 are used in sheaths for our OFCs, giving them exceptional strength and a superior level of protection. To have better control of production, we empower our cables with armouring and other strength members. Our state-of-the-art manufacturing hub also serves as an independent business-vertical to meet the increasing global demands for FRP/ARP Rods and IGFR Yarns. In order to meet the global standards of quality and safety, our OFCs are rigorously tested through high-tech testing equipment like Optical Time Domain Reflectometer, Ribbon Fibre Geometry Measurement System, Spectrum Analyzer, CD/PMD Analyzer, Fibre Geometry Analyzer and other Raw Material Testing Systems like DSC, ESCR, CBC, Hot Air Oven, MFI, CBD, Cone Penetration, drop Point Test Apparatus etc. A stringent adherence to a fool-proof quality control system is ingrained in our mechanism.

With years of experience in manufacturing and supply of OFCs, Polycab Telecom keeps investing in the latest technologies, materials and human resource, vital to meet the highest performance-requirements in telecommunications and surpass its clients’ expectations.